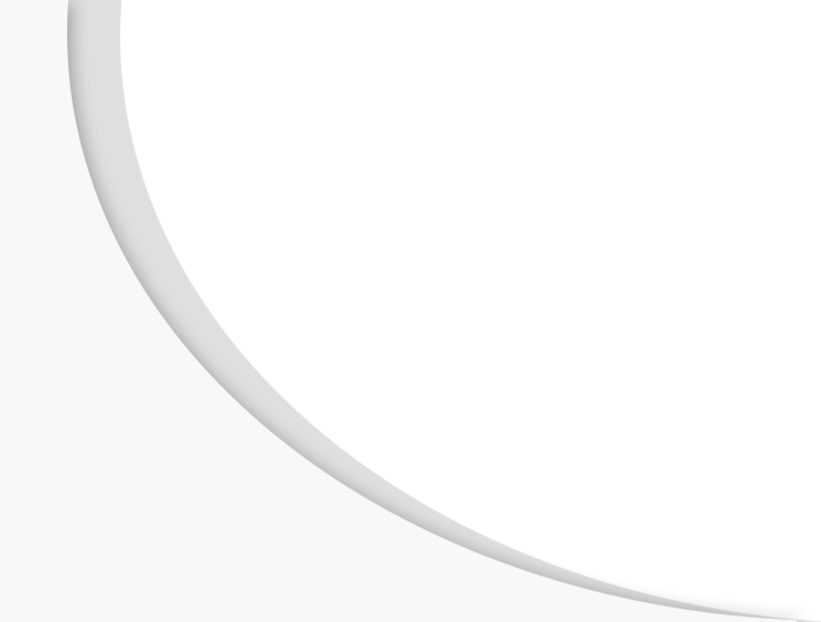

Ceramic Wear Liner Plates

MGI are expert manufacturers and installers of ceramic liner plates – the No.1 choice at over 350 sites in the UK alone.

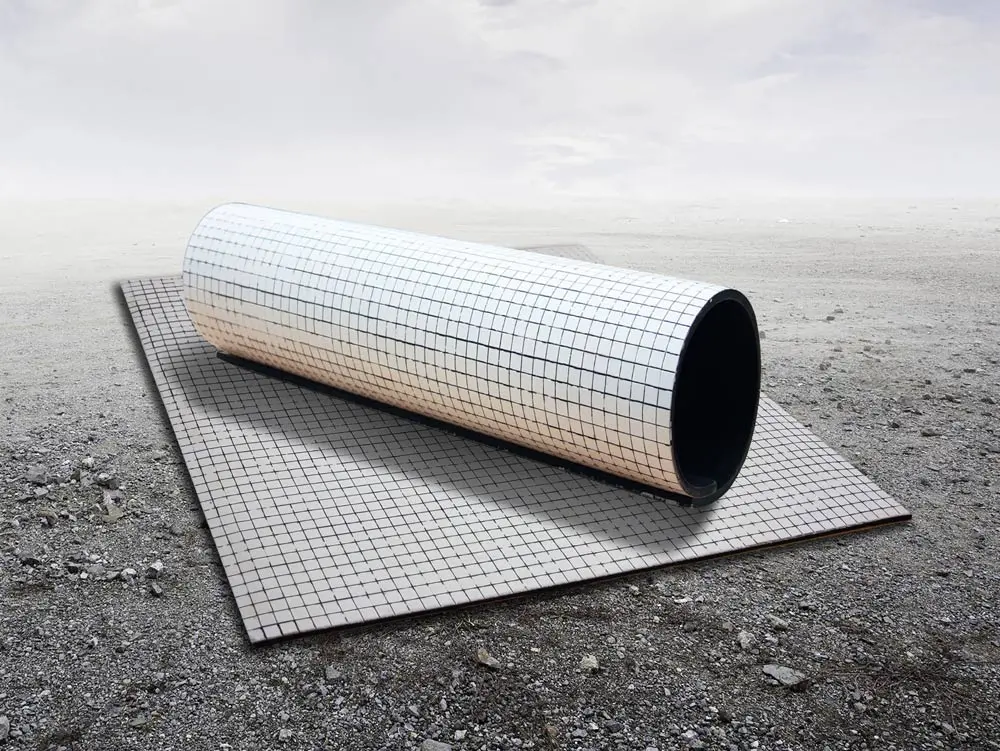

The liner plate consists of ceramic tiles autoclaved onto a rubber and steel backing plate. These liners can be any shape or size, including curved, as specified by the customer.

The backing plate comes with a stud or studs pre-welded in. These studs can be placed anywhere on the plate as required. No rubber on the front wear surface stops the ceramic from washing away, unlike other ceramic liner plates.

The ceramic comes in two thicknesses, 10mm and 20mm, depending on the application. The ceramic liner plates are quick and easy to change – the conventional way of cementing on tiles is time consuming due to the cement having to set before use.

MGI wear liners have a rubber layer between the steel and ceramic, this acts as a shock absorber and significantly reduces cracking and ideal for use on impact areas.

MGI’s conveyor ceramic liner plates can be manufactured in almost any shape or size.

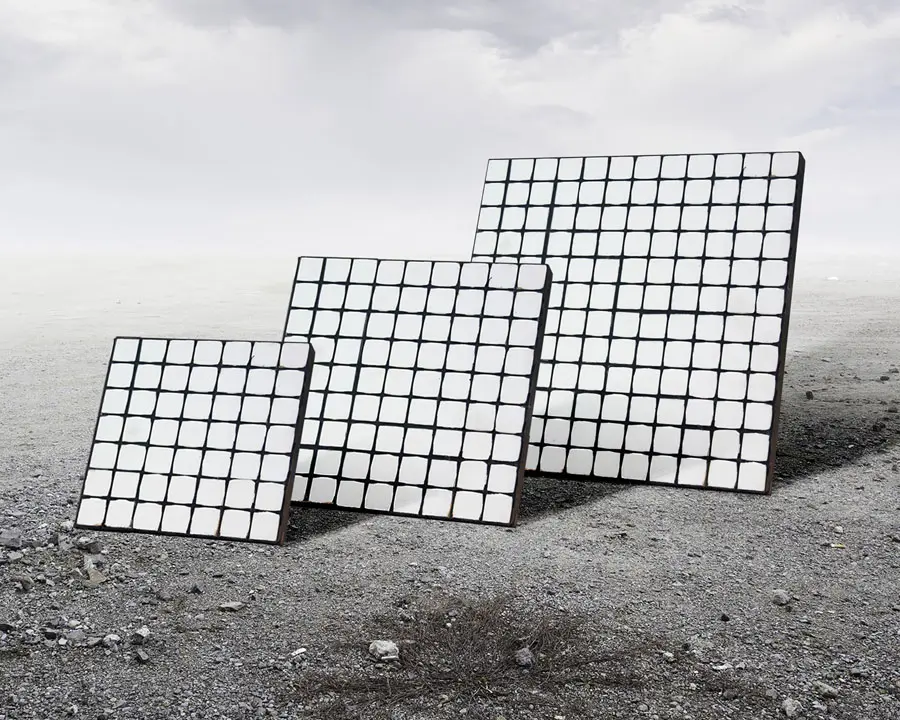

Ceramic Sheets

Ceramic Sheets come in 500mm x 500mm pieces and have two thicknesses of ceramic depending on the application. The first sheet has 3mm thick ceramic with a tile dimension of 10x10mm, this is autoclaved onto 3mm thick rubber.

The second sheet has 4mm thick ceramic with a tile dimension of 20x20mm, this is autoclaved onto 5mm thick rubber.

The sheets are very flexible and can be autoclaved or cold bonded onto flat or curved surfaces without any problems. Ceramic sheets are excellent for lining light duty applications where the 10mm and 20mm thick ceramic liner plates are excessive for your needs.